This section provides an overview of my involvement in our semester two group mobile project. For a more detailed look at the assets I created for the project, refer back to my anthropometrics, 2D model, 3D model and rendering articles.

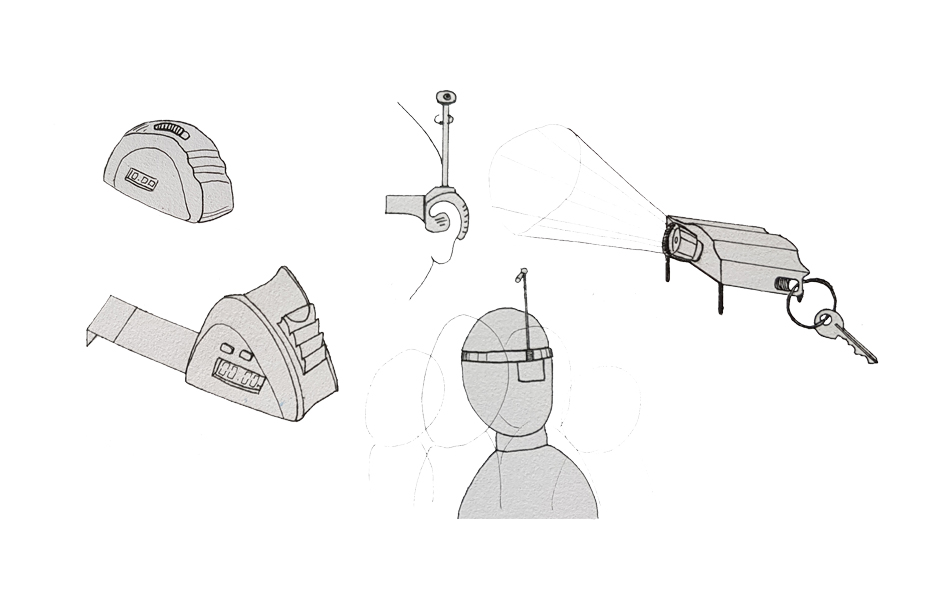

Our brief was to create a prototype for a mobile, portable, wearable, or integrated device. We had several different scenarios to choose from, such as 'going to an entertainment event' or 'ordering food' among others. We thought it best to try and think of an idea for each brief, rather than pick one scenario straight away. My ideas included an electronic tape measure for buying furniture, a miniature projector for presenting to a group and an admittedly rather goofy periscope camera for viewing an entertainment event over the heads of those in front. Here are some of my initial concepts.

Our brief was to create a prototype for a mobile, portable, wearable, or integrated device. We had several different scenarios to choose from, such as 'going to an entertainment event' or 'ordering food' among others. We thought it best to try and think of an idea for each brief, rather than pick one scenario straight away. My ideas included an electronic tape measure for buying furniture, a miniature projector for presenting to a group and an admittedly rather goofy periscope camera for viewing an entertainment event over the heads of those in front. Here are some of my initial concepts.

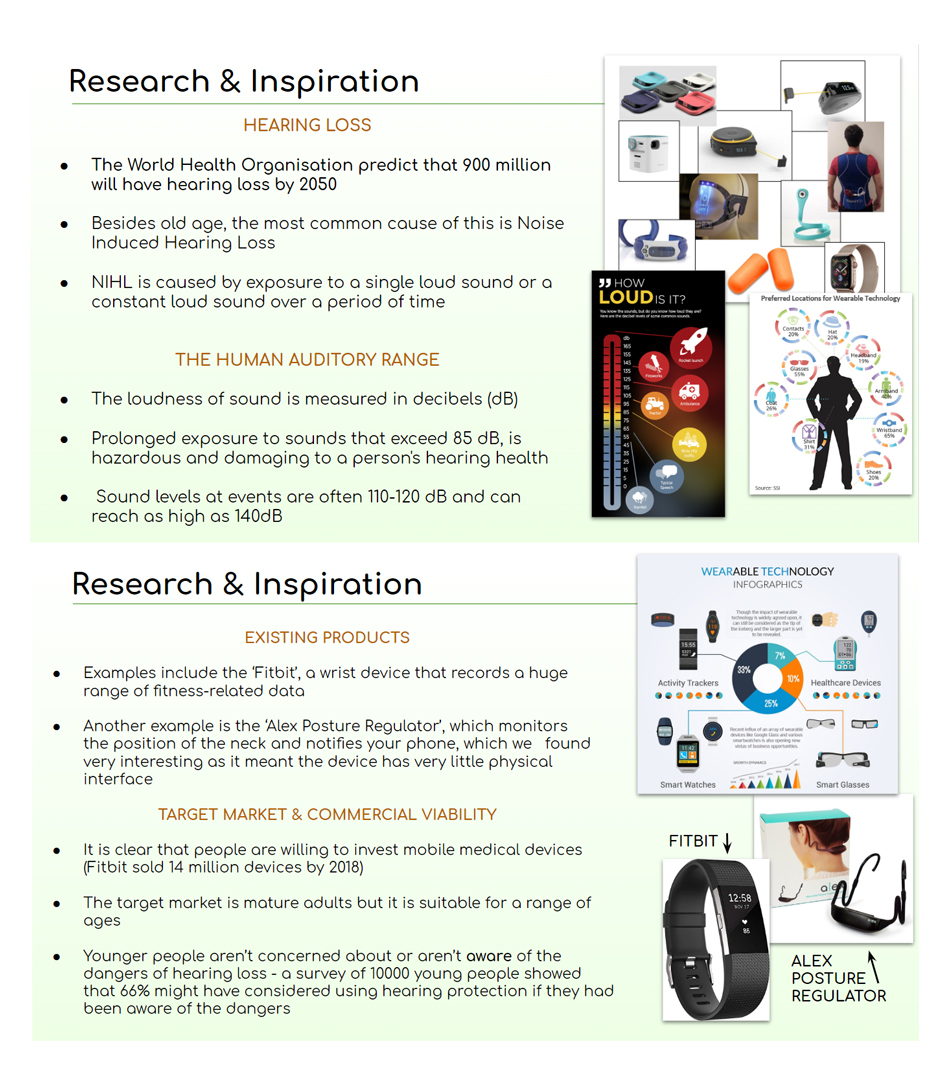

We decided to making a hearing-related medical device. This was in part due to learning that we were expected to make a working prototype since we had a developer on the team, and we thought it would be fairly straightforward to program something that would react to sound input. We also felt there was a genuine gap in the market for this type of product, as you can see from our research below.

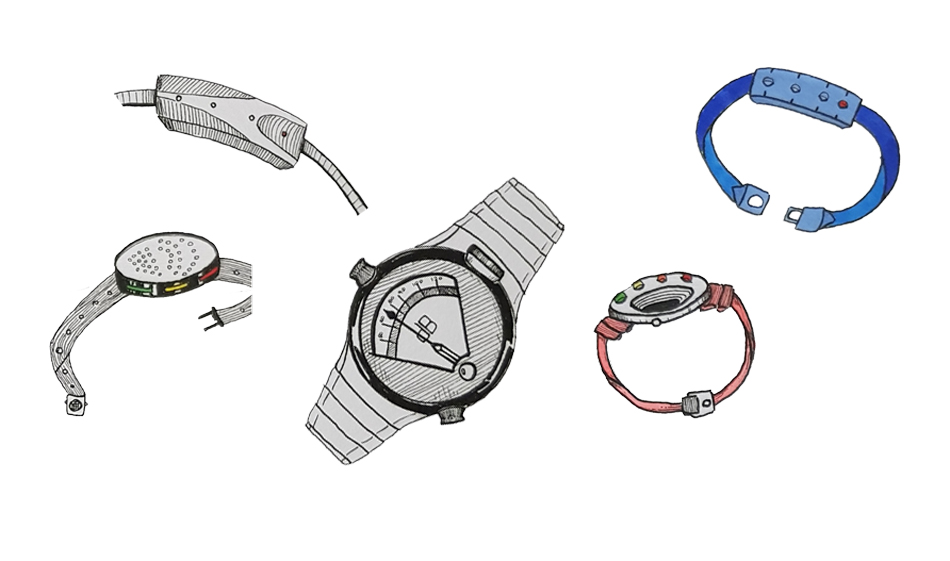

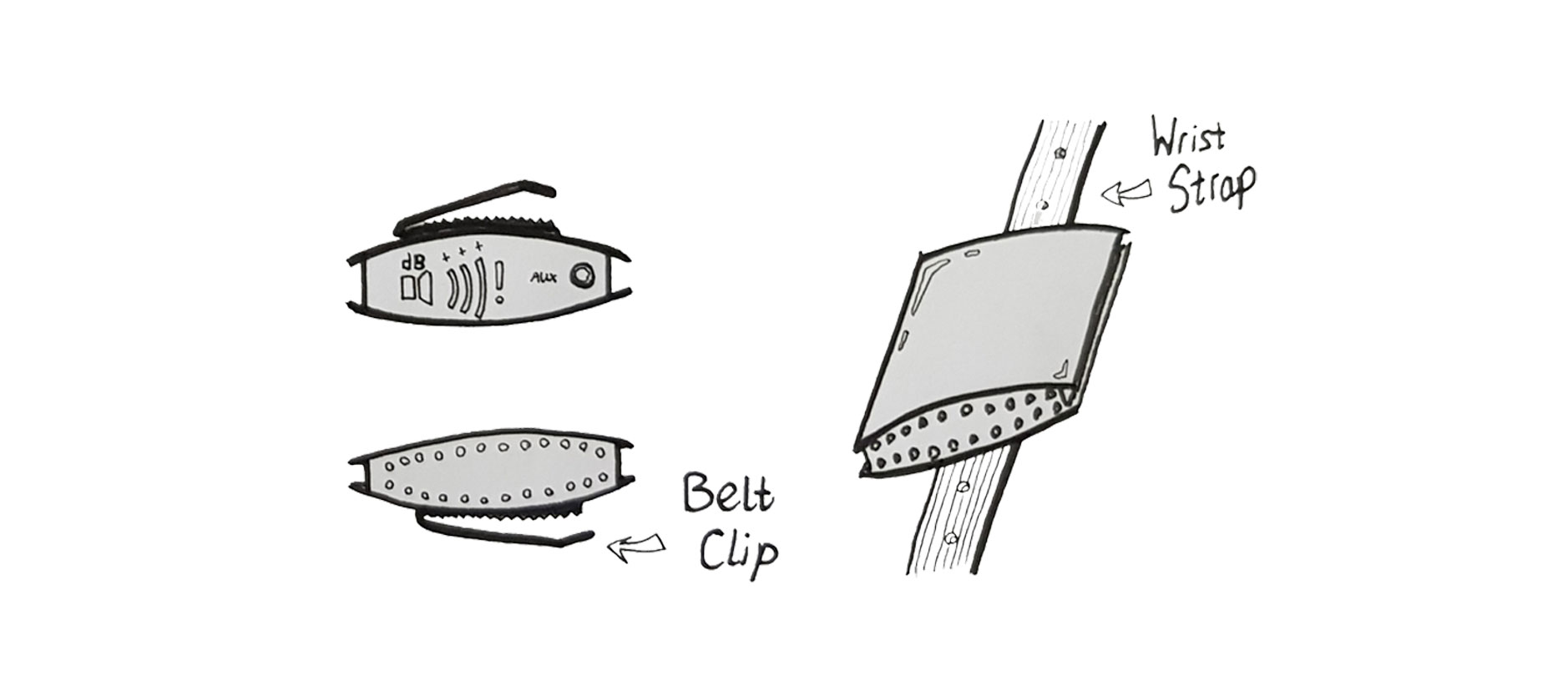

We came up with several requirements for our product. Its main function was to listen to sound levels around the user, such as music at a gig, and alert the user with both a visual indicator on the device and a message/alert to the user's phone or other smart device. Our developer thought this was a good base point to start from as it should be simple to program with easily sourced components. Extra functionality such as a headphone jack for sound amplification (for the hard of hearing) could be added in later, but we wanted to focus on getting a prototype working. The next question was what form this device would take. I came up with a number of wrist mounted ideas as it seemed like the natural place to put a smart device (and we knew that it wouldn't work as intended if kept in a bag or pocket)

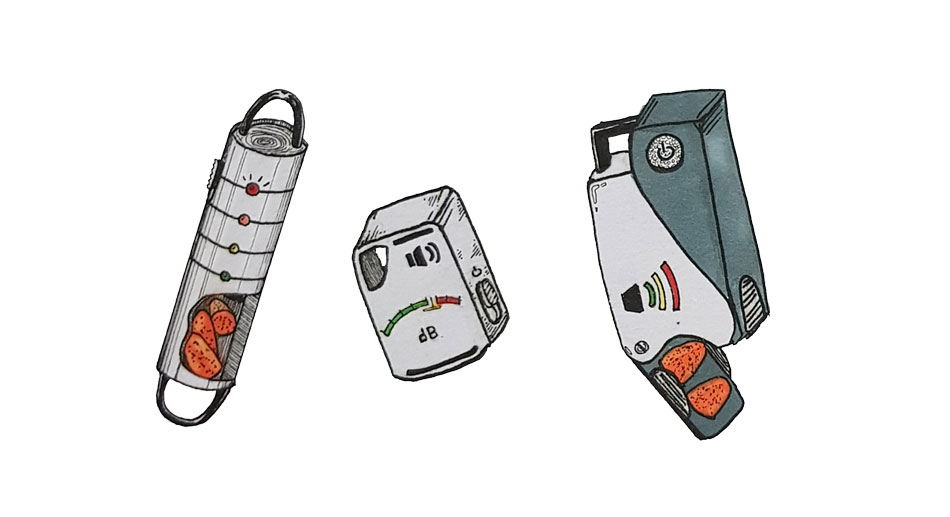

There were a few issues with this though. Our target audience would likely already be wearing a watch and wouldn't want to replace it or wear something on their other wrist. Wrist mounting also demands various physical limitations, such as weight and shape. There was also the danger that the product would somply turn into a smartwatch which wasn't our goal. Based on this I started designing devices to be worn on different ways, such as from a belt, pocket or bag.

After further group discussion and evaluation of my concept, we decided to proceed in a different direction. The tubular design wasn't compact enough and we were concerned that having it hanging from a belt or bag would lead to poor sound readings and potential damage to the product. Instead we investigated designs to be worn in different places such as on the wrist. Since flexibility was desirable, I began to design a product that could be worn in different ways, something modular or convertible.

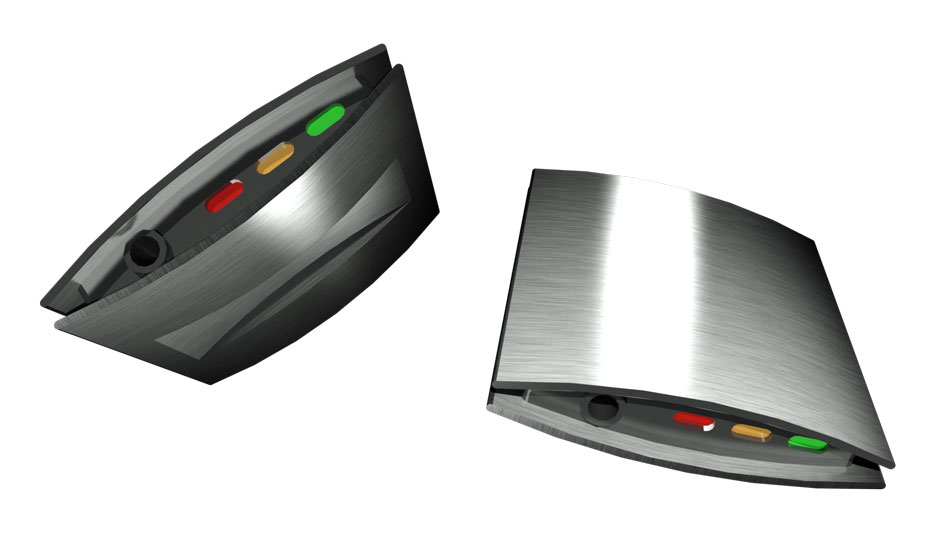

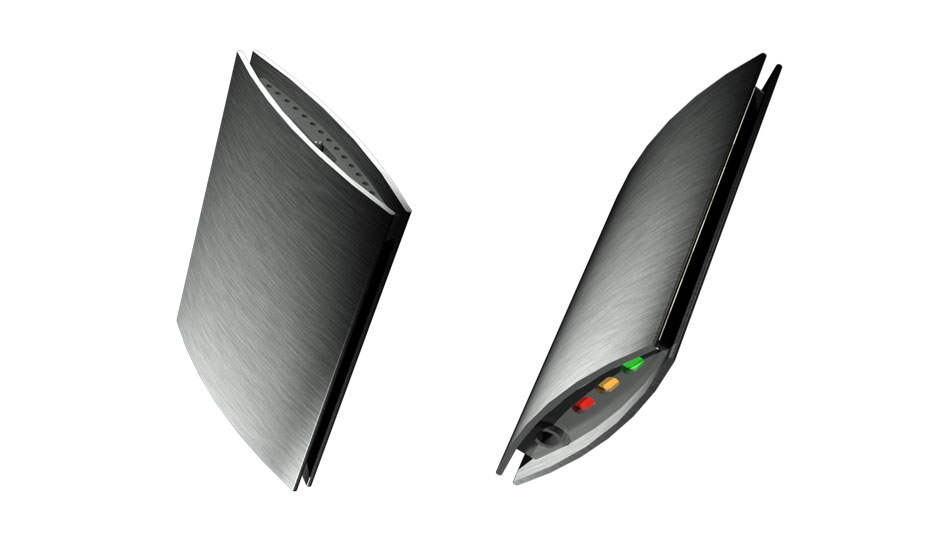

Next I created the 2D and 3D CAD models. You can see how I made these here: 2D model/3D model. Below you can see the specs of our product with a 360 animation I made, plus some of the high-quality renders I produced.

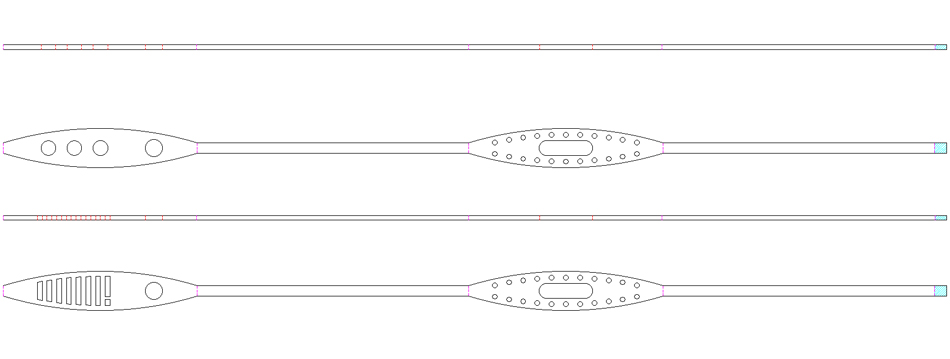

Although it didn't end up being used, I also made a drawing showing how aluminium sheet metal would be cut in order to form the product. I made two different styles because we weren't toally set on the LED layout when I drew this plan. The sheet metal would ideally be cut with a laser. The bent aluminium sheet would provide the product with an excellent strength-to-weight ratio.

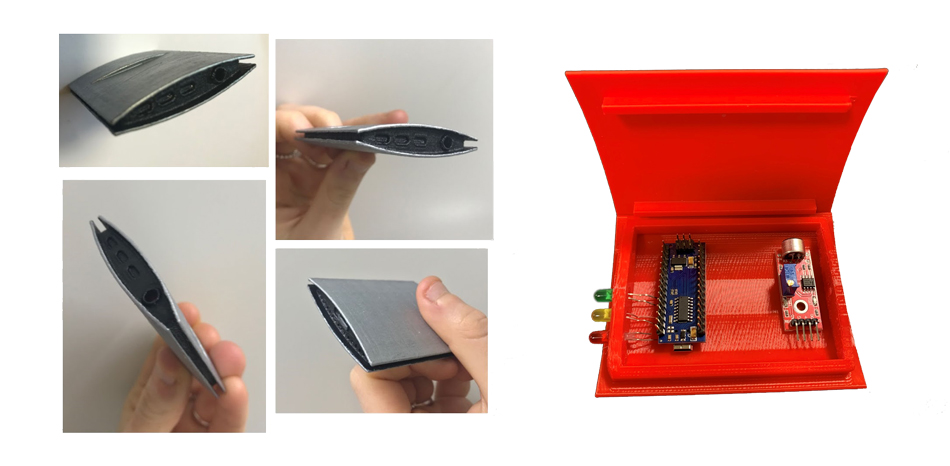

Next we made prototypes using additive manufacturing. I made two different sizes, one was correctly scaled so we could show the real size of the device while the other was scaled up to 2.5x and was made with a detachable lid so the electronics could fit inside. If the product was to actually be manufactured then the internals would be designed to fit. Since this was just a prototype we used the components we had access to which were simply not very compact. Below you can see the smaller prototype kindly painted by team member Lucy, and the larger model left in red.

In addition to my CAD work I had a go at logo design since our designer had been absent at the start of the project. The logo features a shield with an ear and music note inside. This represents how the product is designed to protect your hearing when listening to music. Below you can see the development from drawing to final logo.

Since I had some spare time before the presentation I also made a promotional poster to show the product in use. The image was taken at the Student Union by our developer and features some of my 3D CAD renders. It was made using photoshop.

Below you can view our final project presentation, which contains all of the work we put into the project including how we met the brief. Note that this presentation contains content from Ella Hamilton-Wright, Lucy Hopkins, Dylan Farr and myself. The presentation is not available on mobile devices.