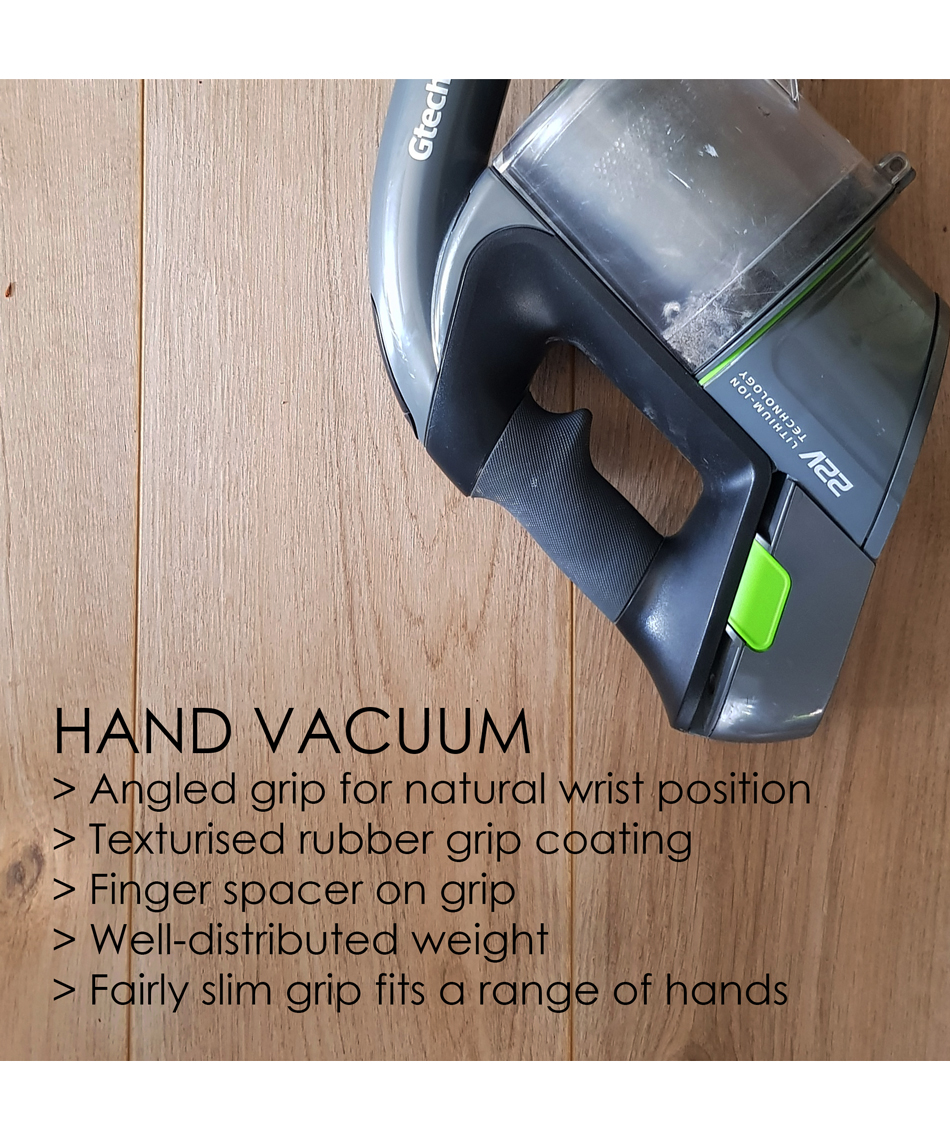

Our final ergonomics and user interaction task was to explore the design of everyday objects (specifically ergonomics) and pick one to improve. This isn't as simple as one might initially think. The study of anthropometrics has been utilised to improve the ergonomics of products for over 100 years. In recent decades it is fair to say that the advances in manufacturing, materials and computer-aided design have meant that many everyday items have reached a peak level of ergonomic perfection; I suspect we have reached a point of diminishing returns where a huge amount of research, development and retooling would most likely result in a product that is only a negligible improvement on its predecessor. To illustrate this point, I took some photos of items around my house and annotated the features that make them so ergonomically sound.

As one might expect, as products get more specialised and/or expensive, their ergonomic qualities tend to improve to the point where only very slight improvements could be made if any at all. Since I had to choose something to improve, I thought it best to focus on reasonably inexpensive items and thought back to some furniture assembly I had undertaken recently. I remembered an issue I had come across with a screwdriver. You can see the issues I had annotated on the image below.

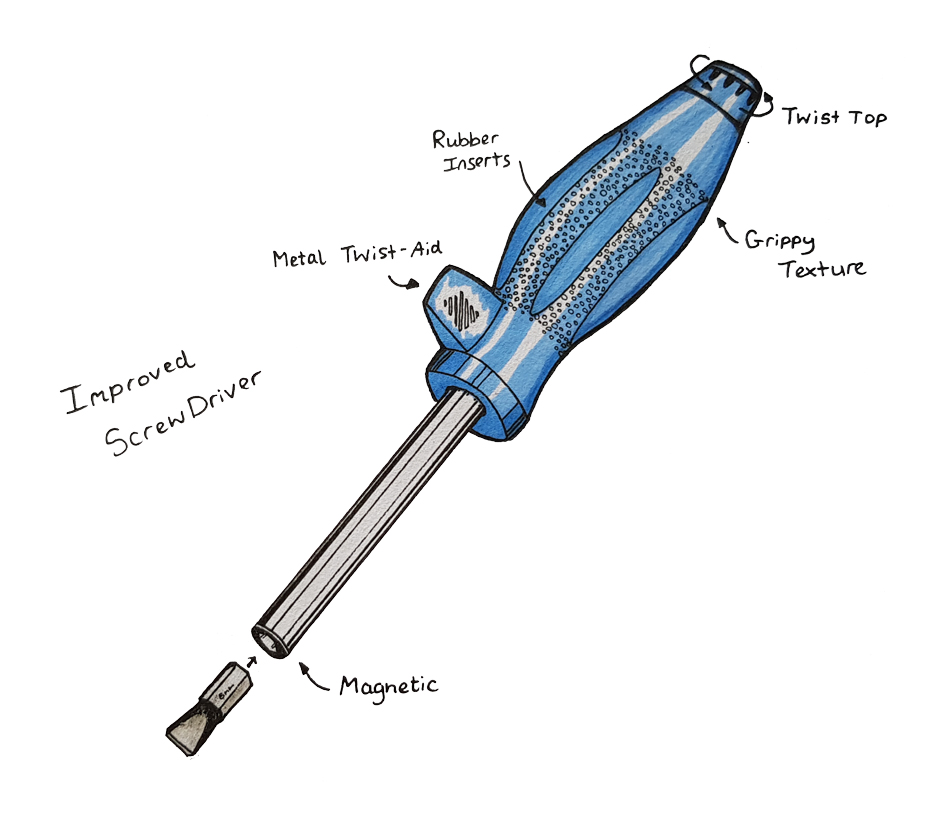

There were three key improvements I wanted to make. Firstly, the handle should have a better texture finish and be made of a gripper material so it could be twisted with more torque. Secondly the metal shaft that holds the interchangeable bits via a magnet would have to be bedded into the handle more securely, so it didn't break free of its adhesive and slip when under load. Thirdly, and purely for convenience, I wanted a spinning section in the end of the grip which can sit in your palm for steadiness while twisting the handle with fingers. This technique is handy for inserting or removing fine-thread screws that don't require much torque but do require lots and lots of turns. I have produced an illustration of my concept that can be seen below.

The key improvement is a metal 'twist-aid' that can be pushed with the thumb to exert extra torque on the handle. This metal extension is fixed to the metal shank rather than the plastic handle so it can't slip like it could before. I created a 3D model on Fusion 360 that shows the two main components.