Every year, the RSA publish a series of briefs as part of their Student Design Awards. These briefs are diverse and cover a range of current world issues, from climate change to human rights. The University has a tradition of using these briefs as a basis for our Second Year, First Semester projects. The research side of the chosen brief forms our Case Study (which is submitted as a report), while our design solution is presented as per the RSA guidelines, this year’s instructions specifying six A3 posters. Here you will find a write-up of my design process followed by my RSA design solution posters.

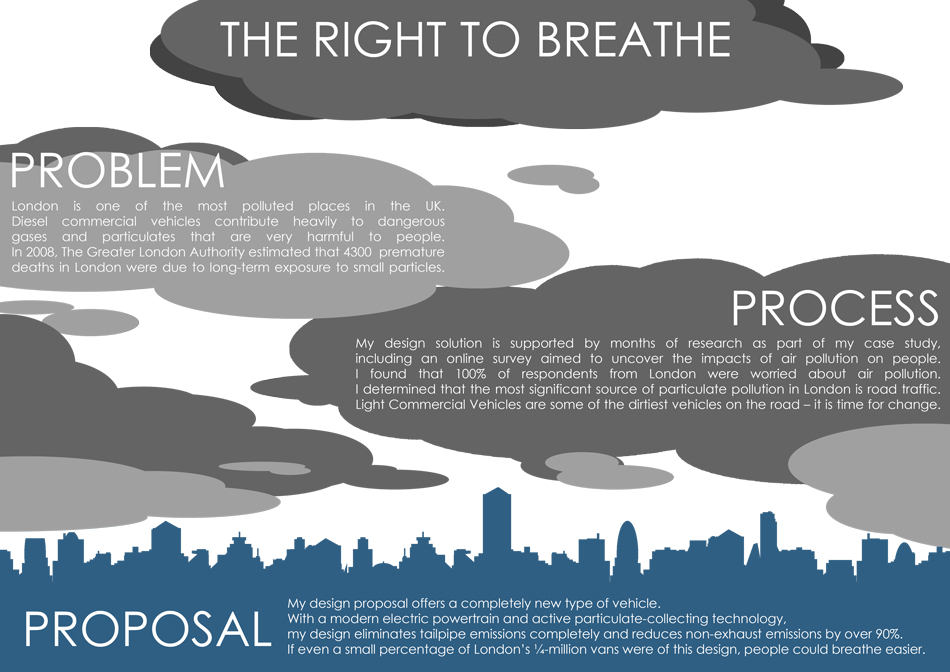

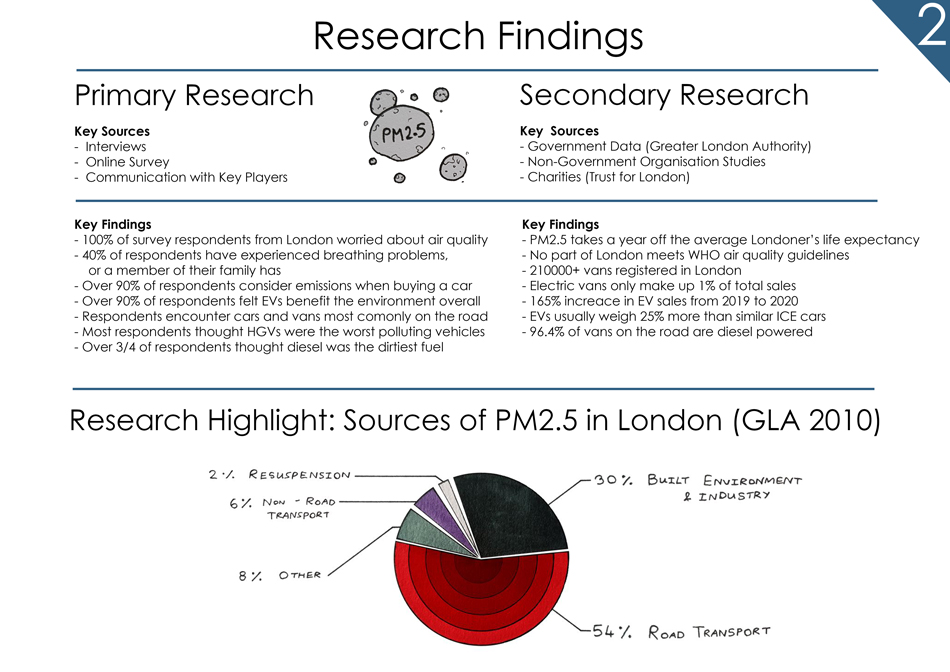

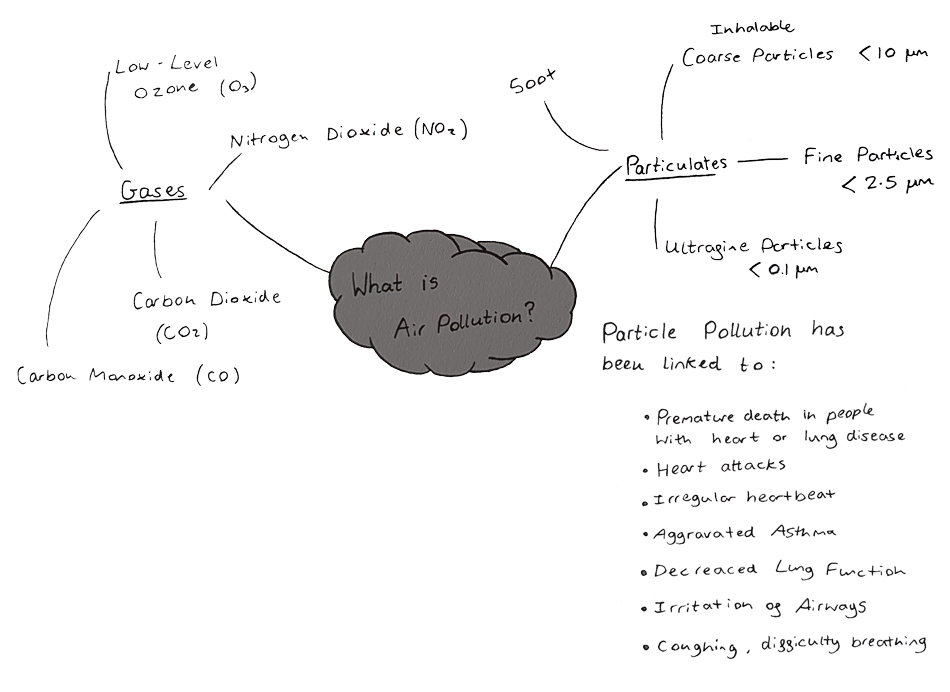

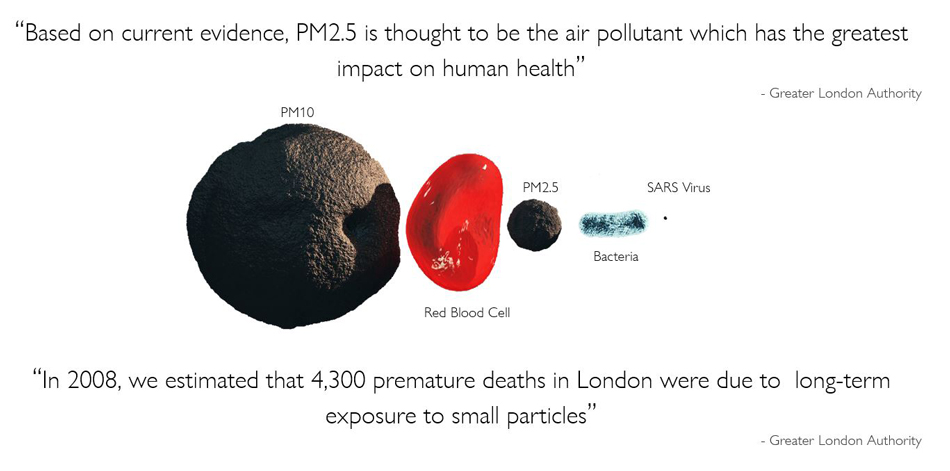

I chose the RSA brief 'The Right to Breathe' which poses the question 'How might we ensure that everyone living in areas with poor air quality is guaranteed their right to clean air?' This question is very open to interpretation, which I think was purposeful as the RSA wanted to encourage a wide range of different solutions from competition entrants. I chose this brief because I have been conscious of air pollution since a young age; it was a key reason my parents moved our family out of London and to the South Coast. This personal connection was why I decided London would be the focus of my study despite there being far more polluted places in the world. I began by investigating exactly what air pollution is, and why London's air is so poor.

I chose the RSA brief 'The Right to Breathe' which poses the question 'How might we ensure that everyone living in areas with poor air quality is guaranteed their right to clean air?' This question is very open to interpretation, which I think was purposeful as the RSA wanted to encourage a wide range of different solutions from competition entrants. I chose this brief because I have been conscious of air pollution since a young age; it was a key reason my parents moved our family out of London and to the South Coast. This personal connection was why I decided London would be the focus of my study despite there being far more polluted places in the world. I began by investigating exactly what air pollution is, and why London's air is so poor.

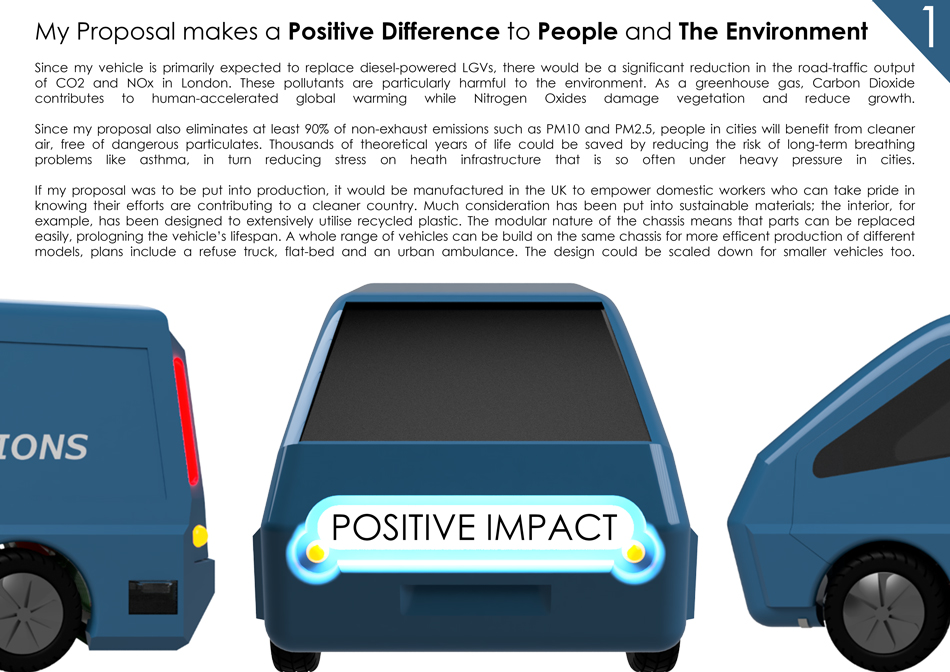

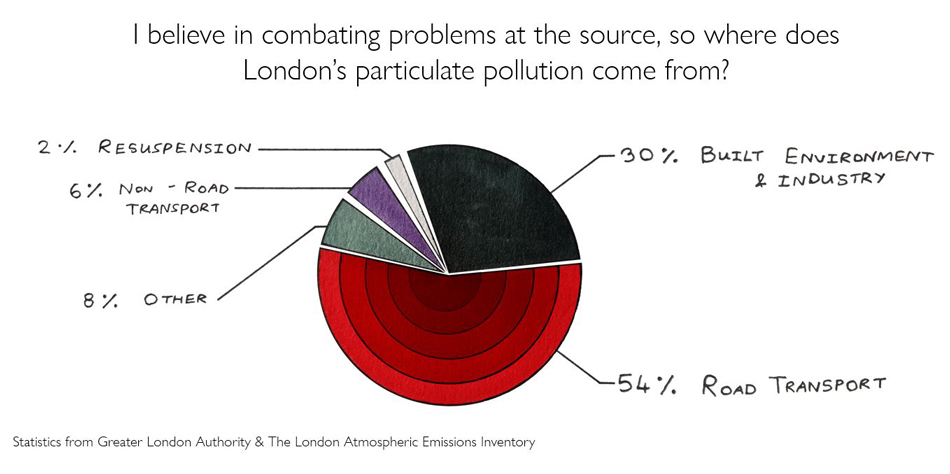

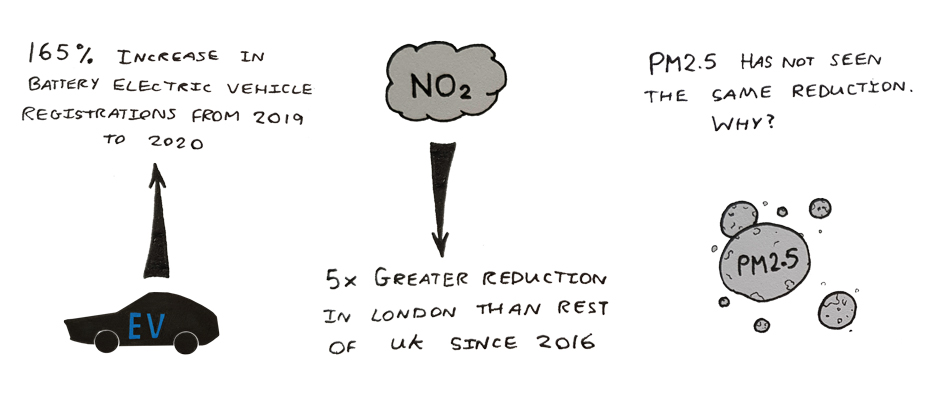

My research found that the majority of particulate pollution in London comes from road traffic, specifically passenger cars. Many people believe that the solution is electric cars, which have zero exhaust emissions. This is great in reducing levels of toxic gases like Nitrogen Oxides and Carbon Dioxide, but particle emissions remain high.

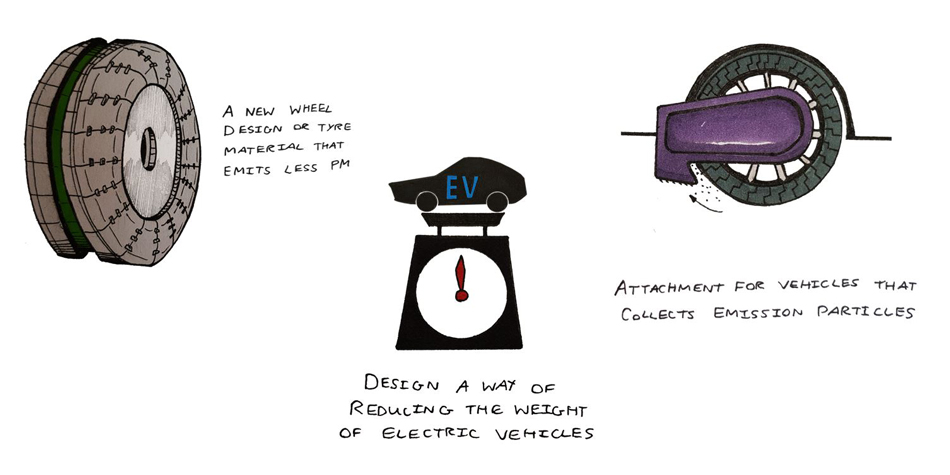

This is because all road cars, even electric-powered, emit Non-Exhaust Emissions which occurs through tyre wear, brake wear and resuspension of particles on the road. According to the UK National Atmospheric Emissions Inventory, particles from brake wear, tyre wear and road surface wear currently constitute 60% and 73% (by mass), respectively, of primary PM2.5 and PM10 emissions from road transport. This means that the majority of particle emissions come from non-exhaust sources; switching to electric does not solve this. I discovered that most electric vehicles actually produce more of these emissions than comparable internal-combustion engine cars because they typically weigh at least 25% more. Extra weight causes more brake wear since the brakes must work harder to fight the car’s momentum, and the increased friction on the road means the tyres wear faster. Having found a major source of the problem, I narrowed my investigation down to answer the following question: How can electric vehicles be modified or redesigned to reduce non-exhaust emissions in London? Below are some of my initial ideas.

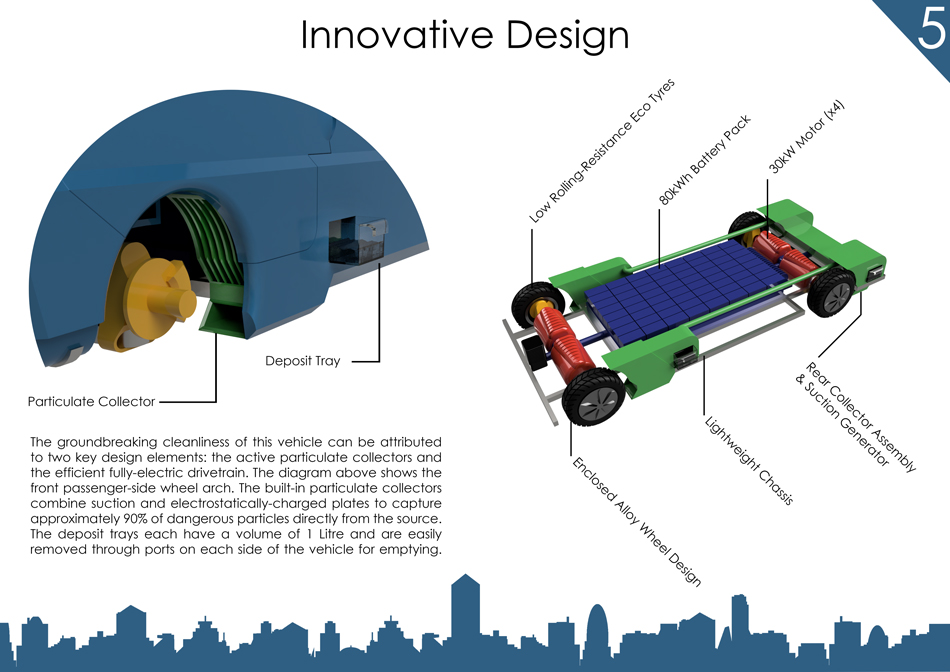

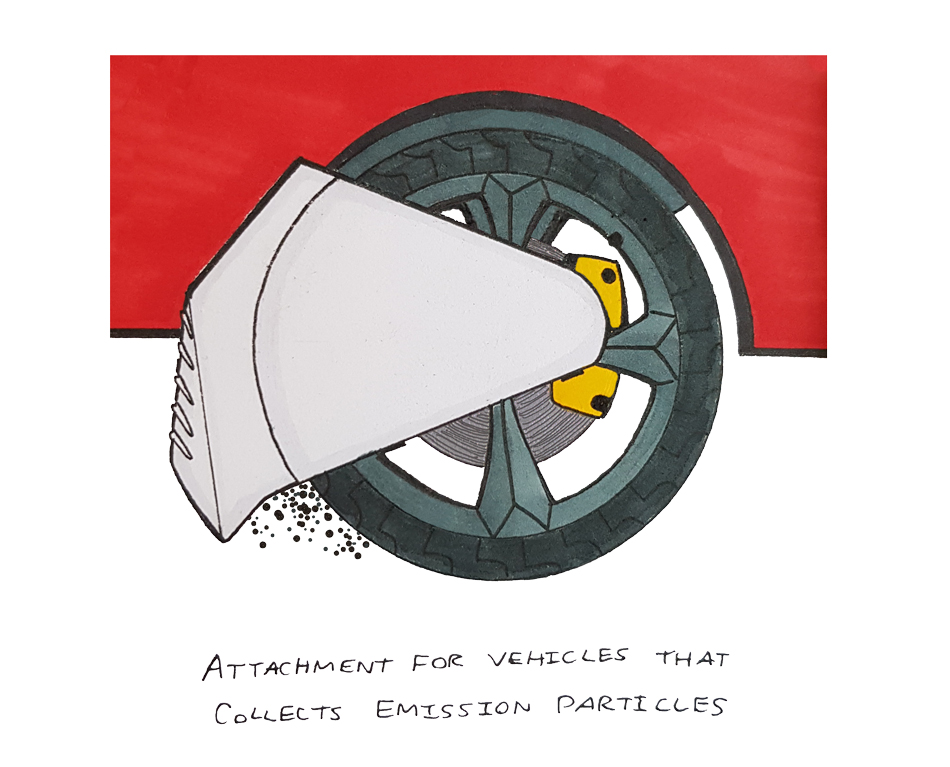

The wheel attachment idea seemed the most viable idea since vehicle manufactures are already trying to develop lighter EVs and tyre manufactures are always making improvements to tyre compounds. I continued to develop this idea; my goal was primarily to make it functional, but also as stylish as possible so the aesthetics of the host vehicle wouldn’t be completely ruined.

I was nearing the CAD stage of my project when I came across an identical product that was revealed in 2020. The Tyre Collective had won the UK James Dyson Award with their particle collection device which my concept was remarkably similar to. I had been completely unaware of this product up until this time, it was simply a case of two independent efforts coming to the same conclusion independently. This was a major setback as I couldn’t continue working on a product that already existed, but it was encouraging to know that the idea actually worked. I was sure the concept could be improved on, so I went back to the drawing board and found a new focus: light goods vehicles.

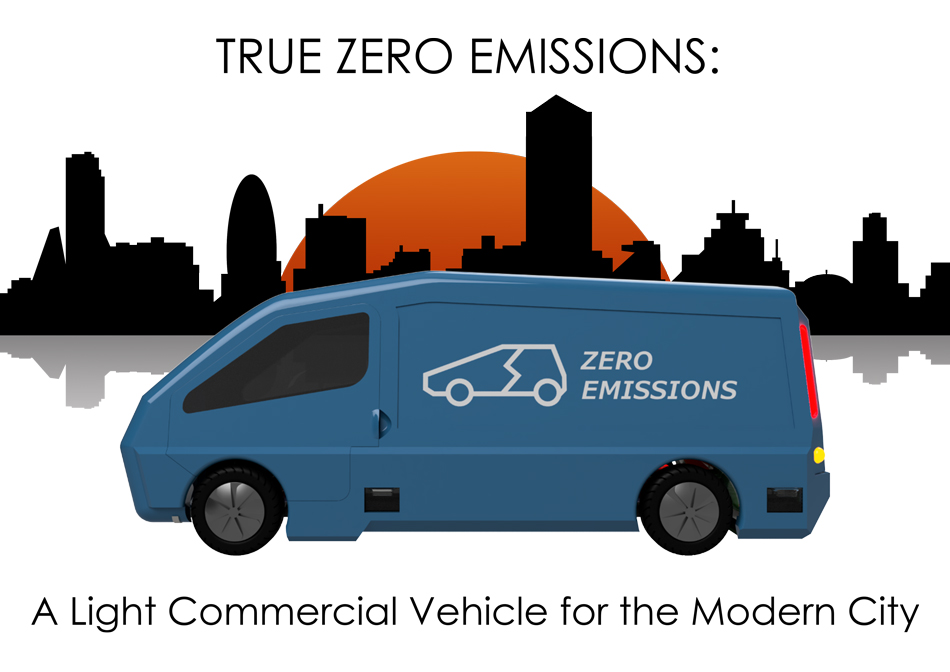

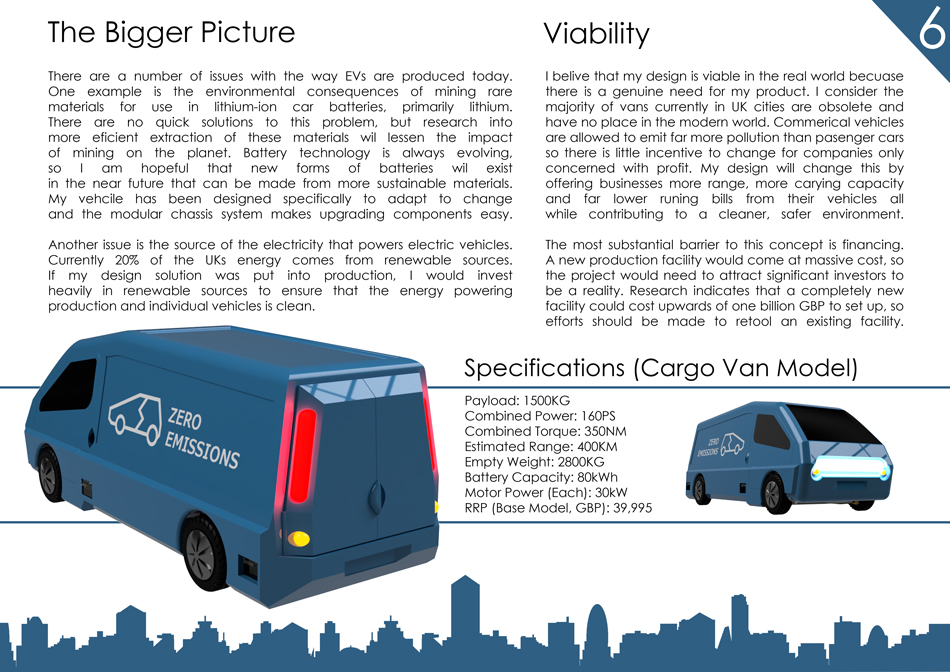

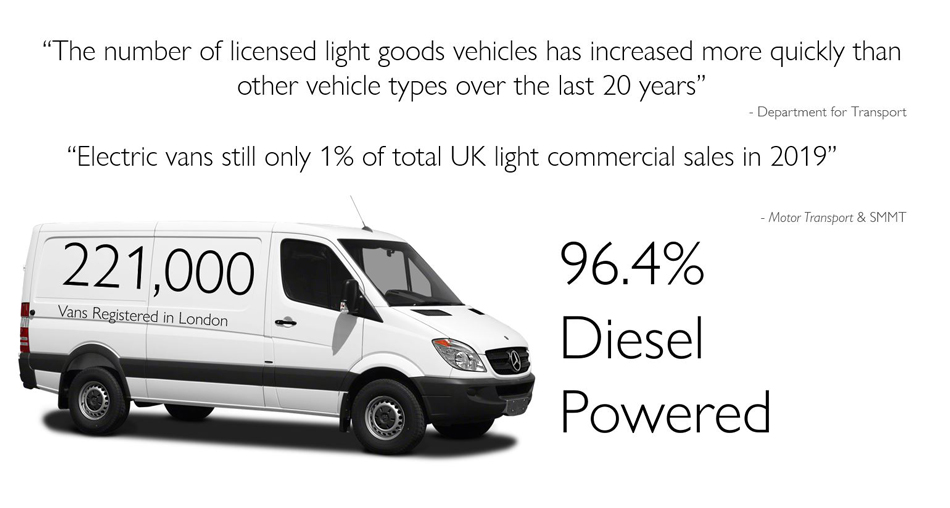

Compared to the passenger car market which has shown a reduction in diesel vehicles sold over the last few years, light goods vehicles are almost exclusively diesel powered. Electric options are very limited and the models that are available are not especially attractive to potential buyers for several reasons. Firstly, they offer reduced load capacity over conventional vans. They also have greatly reduced range over diesel vans. Range can be increased by adding bigger battery packs, but this reduces cargo space further. New electric vans are also up to 50% more expensive than a new diesel van. Creating an attractive alternative was a challenge! First, I created a mood board to help inspire my designs. Images courtesy of Pinterest.

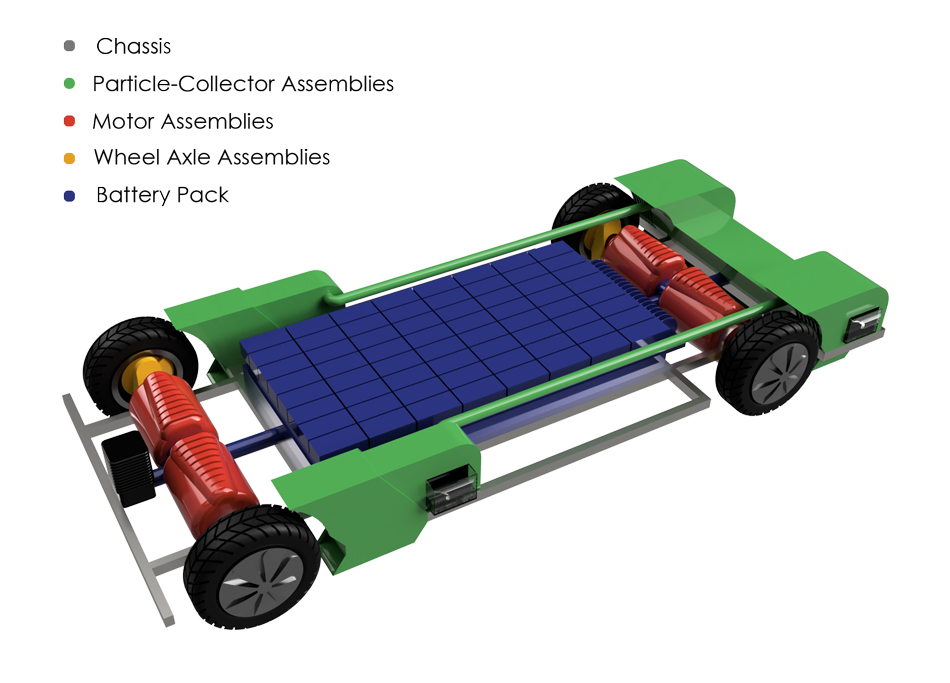

There are certainly lots of concepts out there, but comparatively few that have made it to market. I could simply design another electric van concept, but as I determined in my case study, ‘just’ being electric isn’t enough to make a real difference to particulate pollution. I decided that the best way forward was to integrate my earlier particulate-collecting technology into a unique and competitive electric light goods vehicle. This was one of my most ambitious projects to date, designing a new vehicle from the ground-up is no easy task! First, I started by designing a chassis. I wanted the chassis and drivetrain to be as modular as possible so multiple versions of the vehicle could share components, a van and a bin lorry for instance. I used Fusion 360 to create all my 3D models.

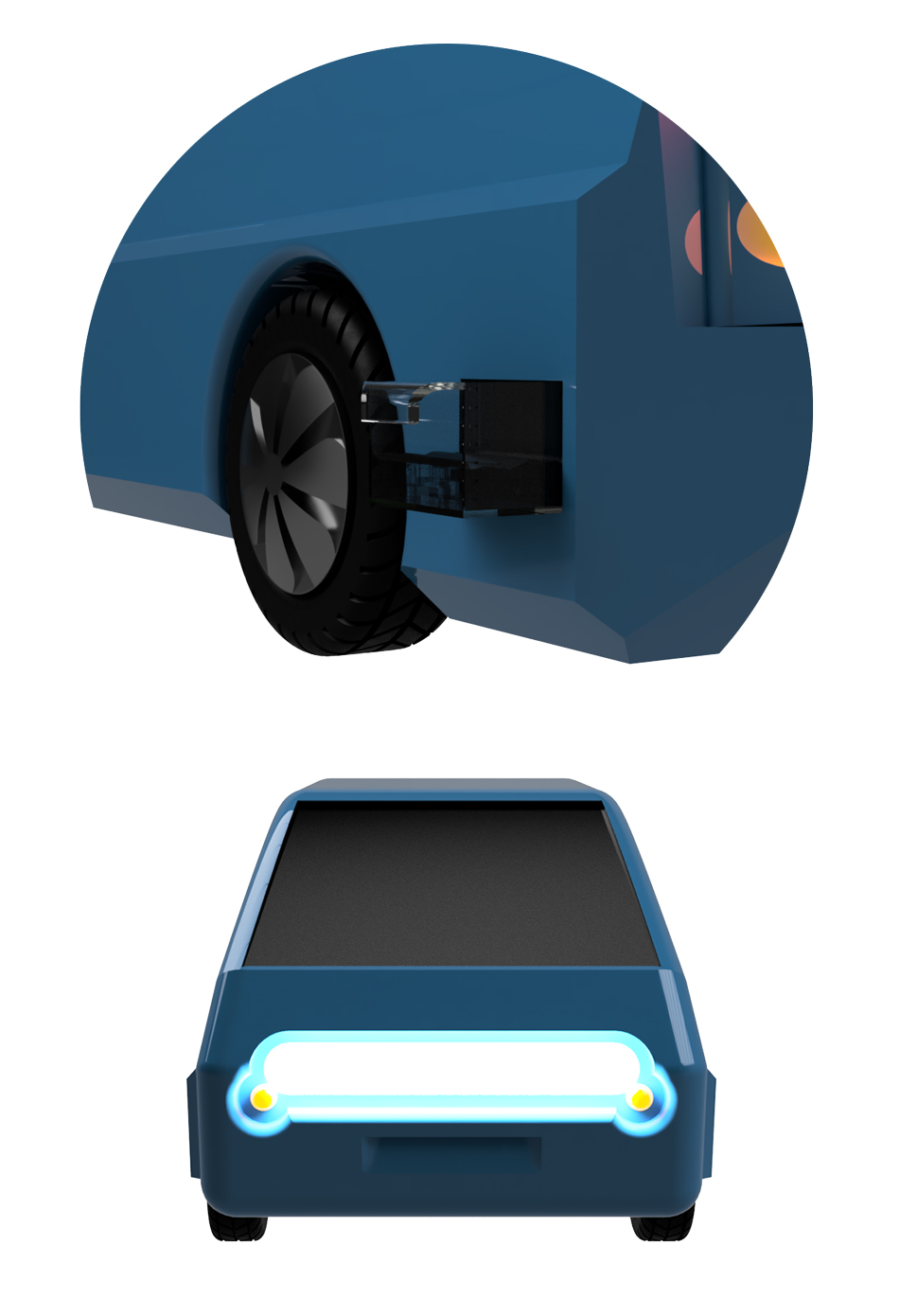

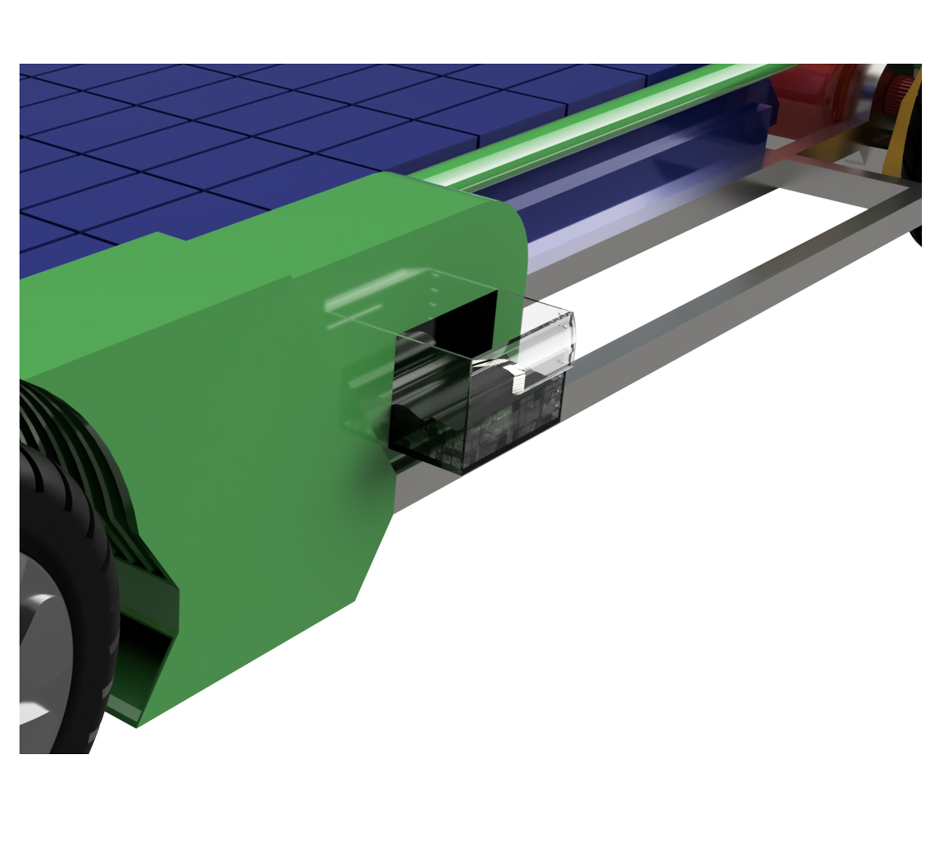

This chassis has several innovative features, the most important of which are the integrated particle collectors and the four collection trays placed around the frame. These plastic trays collect the particle deposits from the filters for easy disposal. I estimate that the trays will have to be emptied once every 7-10 days of regular city driving. The render below shows one of the trays being removed for cleaning. They are only removable when the vehicle is stationary and unlocked.

The next part of my project was to design the body of the vehicle. The biggest challenge here was to make the design as practical as possible while keeping the vehicle compact and stylish. I believe my solution meets these requirements and is the perfect delivery vehicle for the city. I decided on a pale-blue colour scheme as this is associated with electricity and I think has a calm, clean look. To complete the visuals I designed a logo on Photoshop and added it to each side of the vehicle. I have not yet decided on a brand name for my concept.